Plastic pallets are large, durable, cheap 2023

Currently, plastic pallets have become essential items in the industrial and commercial sectors. Plastic pallets are made from high-quality plastic, which not only ensures high durability but also helps protect the environment. Refer to the article below to learn about the features, advantages, durability of plastic pallets, as well as useful tips for selecting, using, and storing plastic pallets to optimize your transportation and storage processes.

What are plastic pallets?

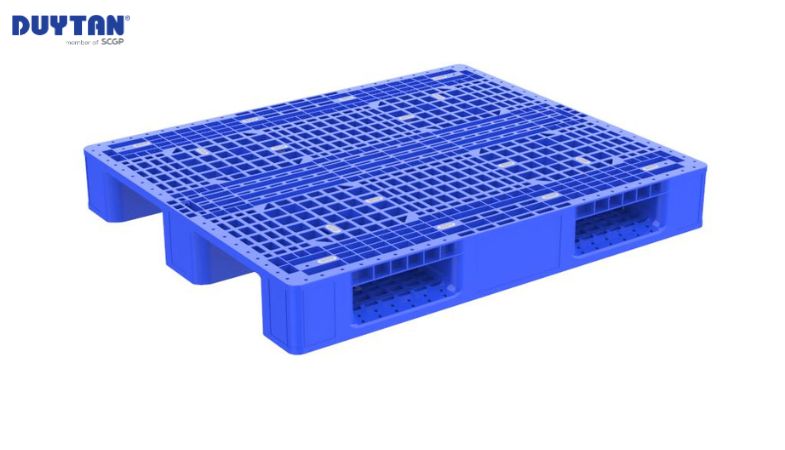

Plastic pallets are products made from molded HDPE (High-Density Polyethylene) or PP (Polypropylene) plastic pellets, with a flat structure and high strength. They have excellent load-bearing and impact resistance capabilities, making them widely used for stacking and storing goods.

Applications of plastic pallets

Plastic pallets are widely used in various industries and sectors, particularly in loading and unloading and warehousing. Specifically:

- Used for various purposes such as product pallets, stock pallets, floor lining, and warehouse shelving.

- Protect goods from moisture and mold when placed on the floor.

- Facilitate the scientific arrangement of goods and save storage space by using 2 or 3-tier racking systems that can be stacked.

- Combined with forklifts to move and handle heavy or fragile goods more efficiently.

- Reduce labor intensity by using specialized forklifts with pallets for lifting and handling goods instead of manual lifting.

Popular types of pallets in the market

Based on the production material, plastic pallets can be divided into two main types:

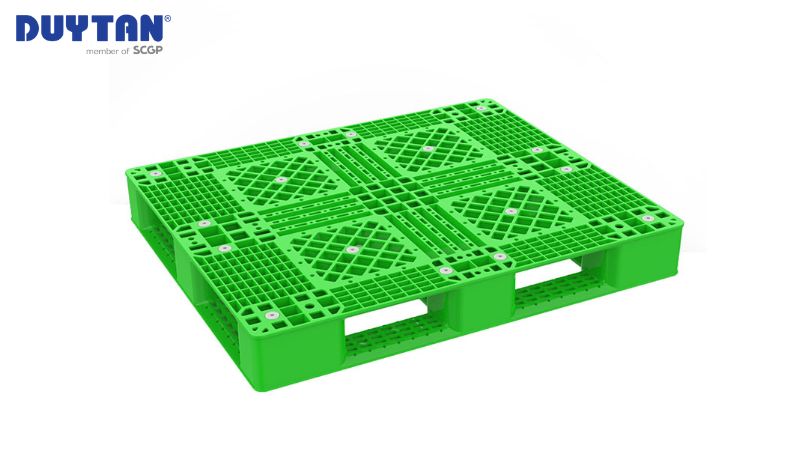

- Recycled plastic pallets: These are pallets made from used plastic and are often black in color.

- Virgin plastic pallets: These are pallets molded from high-quality new HDPE plastic pellets and are typically available in green, red, and yellow colors.

Based on size, plastic pallets can be distinguished as square and rectangular-shaped.

Based on usage, plastic pallets can be categorized as follows:

- Single-sided plastic pallets: They come in various sizes and have good load-bearing capacity, making them commonly used for transportation or stacking of goods in warehouses.

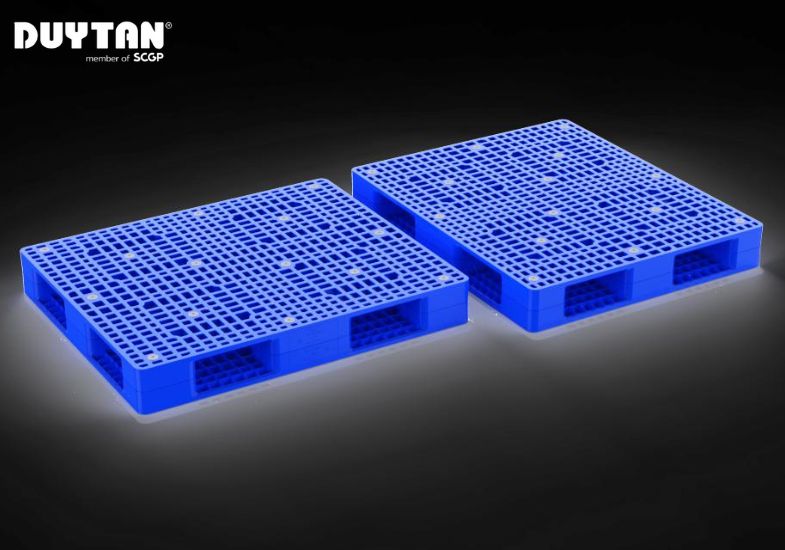

- Double-sided plastic pallets: They can be easily stacked on top of each other, saving warehouse space.

- Open deck plastic pallets: Used for goods that require ventilation, ensuring the preservation of goods without damage.

- Closed deck plastic pallets: They have a solid surface, high load-bearing capacity, and can be stacked on top of each other.

The popular plastic pallets on the market today

Advantages of plastic pallets

-

Transporting heavy loads: For heavy and bulky goods, transportation can be extremely challenging without the support of appropriate tools. Each new plastic pallet can withstand a load of up to 5-6 tons without breaking or deforming, providing peace of mind on every shipment.

- Easy and organized goods arrangement: Plastic pallets facilitate the systematic arrangement of goods, optimizing storage space to accommodate more items. Goods can be stacked on pallets and lifted using forklifts, creating multiple layers of goods. This allows businesses to manage goods more effectively, save time searching, and maximize storage space.

- High durability of plastic pallets: Plastic pallets are made from high-quality plastic pellets, providing them with excellent durability and the ability to withstand strong impacts. After prolonged use, if they become damaged, they can be recycled, saving costs and protecting the environment.

- Waterproof, moisture-resistant, and pest-resistant: Plastic pallets have the ability to resist water, moisture, fire, and other unfavorable conditions, ensuring the protection of goods.

Arrange goods easier to be more tidy with plastic pallets

Although plastic pallets have many advantages, they still have some disadvantages, such as fixed mold patterns, high costs for custom-sized pallets, and complex manufacturing processes.

Pricing of plastic pallets

The price of plastic pallets varies over time based on various factors such as market fluctuations, material type, and design. Typically, plastic pallet products at Duy Tân have prices starting from...

If you are interested in Duy Tân's plastic pallet products, please contact us via email or call us directly to get detailed pricing and advice on the most suitable shipping methods.

Factors affecting the price of plastic pallets

Plastic pallet production materials

Material used for plastic pallets: Different materials used in the construction of plastic pallets will result in different prices and durability. Currently, there are three basic types of plastic materials in the market:

-

Virgin HDPE plastic: This refers to plastic pellets that have not been recycled.

- Recycled HDPE plastic: This is plastic that has been recycled at least once, and the number of recycling times is marked on the product. The more times

- a plastic pallet has been recycled, the lower the price and the lower the quality.

- Recycled PP plastic: Almost all black plastic pallets you commonly see are made from recycled PP plastic.

Material is one of the factors that influence the price of plastic pallets

Plastic pallet load

The next important factor that affects the price of plastic pallets is the load capacity. The load capacity of a plastic pallet refers to the total weight of the goods it can bear. Pallets with different load capacities will have different price ranges.

.jpg)

The load affects the price of plastic pallets

Price Difference between New and Used Plastic Pallets

The price of new plastic pallets is generally higher than that of used ones. Additionally, new plastic pallets offer better quality and ensure absolute safety for users.

Design of Plastic Pallets

Two-sided plastic pallets require more processing and raw materials to manufacture, so they usually have higher prices than one-sided pallets. However, two-sided plastic pallets have higher durability and load capacity compared to one-sided pallets.

Similarly, enclosed plastic pallets will be more expensive than open-grid designs. If you are using pallets for the food or pharmaceutical industry, it is recommended to choose enclosed pallets to ensure the goods are protected and well-preserved.

1 -sided plastic pallet has a low load, so the price is cheaper than 2 -sided plastic pallets

Production Process of Plastic Pallets

The production process of plastic pallets is relatively complex and involves several stages with three basic steps:

Step 1: Selecting suitable raw materials to create the best pallet sheets.

Step 2: Designing and processing molds for each product based on size and provided drawings.

Step 3: Using the molds to produce high-quality plastic pallets, followed by finishing the products according to customer requirements.

Applications of Plastic Pallets in Handling Goods

Used in warehouses and factories

Used in warehouses and manufacturing facilities: Plastic pallets are widely used in warehouses and factories for stacking and storing goods. These pallets are intended for long-term storage and do not require frequent movement, so they do not need to withstand high dynamic load capacity. Therefore, if you are a warehouse owner, it is advisable to choose lightweight pallets for storing goods.

.jpg)

Use plastic pallets to prescribe goods in warehouses

Pallets used in combination with hand forklift or lift

In order to reduce the cost and time of freight between manufacturing or export companies, forklifts have been developed and exist in parallel with the introduction and development of the pallet. The forklifts today have become modern and increasingly improved, and is able to integrate with many pallets. Goods are placed on the pallet surface, pallets are designed to lift goods and coordinate smoothly with forklifts.

All goods on the pallet are lifted and moved to another location. Therefore, just one forklift driver can move a few tons of goods at a time.

Important criteria when choosing plastic pallets

- Choosing the right size: Size is an important factor when choosing plastic pallets because it will directly affect the work performance. If choosing a too large pallet size will waste the space for goods, costly and especially can damage goods when not fixed in the transport process.

- Plastic material: When choosing plastic material, prioritize products made from HDPE because this plastic is durable, ultraviolet resistance and very safe for users.

- Pallet brand: Should choose long -standing brands, with many quality products and good care services

- Plastic pallet price: This is an important factor you need to consider to ensure buying quality products and the best price. You should contact many providers to ask about the price and make the most suitable choice.

Size is an important factor when choosing plastic pallets

Effective Use of Plastic Pallets

Using plastic pallets correctly can increase their lifespan from 60% to 95%, helping businesses improve work efficiency and save costs. To extend the lifespan of pallets, consider the following:

- Avoid sudden and continuous temperature changes from high to low environments, as this can reduce the quality of plastic pallets.

- When using pallets for storing goods, avoid placing them in damp locations to protect and prolong their lifespan.

- Inspect pallets before use, and if any cracks or damage are detected, replace them with new pallets to ensure the safety of your goods.

Frequently Asked Questions about Plastic Pallets

Is the transportation cost of goods using plastic pallets cheaper than using wooden pallets?

Due to their lighter weight, plastic pallets generally incur lower transportation costs, whether by road, sea, or air.

Where are plastic pallets used?

Plastic pallets are used by chemical companies, transportation companies, and export businesses for stacking and moving goods with forklifts.

What is the lifespan of plastic pallets?

The lifespan of plastic pallets depends on the material, environment, and usage. Generally, plastic pallets can last from 5 to 10 years.

Are plastic pallets more durable than wooden pallets?

In terms of structure and material, plastic pallets are stronger and more durable than wooden pallets because they are molded as a single piece and made from resilient plastic materials.

Is plastic durability better than wooden pallets?

In terms of structure and material, plastic pallets will be more durable and stronger than wooden pallets because they are cast monolithic and made from durable plastic material.

Duy Tân - A reliable manufacturer and seller of durable, high-load capacity, and competitively priced plastic pallets

We take pride in being a pioneer in manufacturing plastic household, packaging, and industrial products. At Duy Tân, we are committed to delivering high-quality plastic products at the most competitive prices.

We offer a wide range of plastic pallets with various sizes and colors to meet your specific requirements. If you are looking to purchase quality and affordable plastic pallets, please contact us directly for detailed pricing and consultation.

Contact Information:

- Address: 298 Ho Hoc Lam, An Lac Ward, Binh Tan District, Ho Chi Minh City, Vietnam

- Phone: +84 28 3876 2222 - Line: 268

- Email: info@duytan.com